ASNT Level II in Radiography Testing

Product Details:

ASNT Level II in Radiography Testing Price And Quantity

- 7000 INR/Number

- 1 Number

ASNT Level II in Radiography Testing Trade Information

- At our Industrial Facility / Training Institute in Greater Noida

- Cash on Delivery (COD) Delivery Point (DP) Cash Advance (CA) Cash in Advance (CID) Cheque

- 50 Number Per Week

- 5 Days

- Yes

- Contact us for information regarding our sample policy

- Level II classes are taken by ASNT NDT Level III certified Engineer.

- North India

- NDT Level II in RT as per ASNT's written practice SNT-TC-1A

Product Description

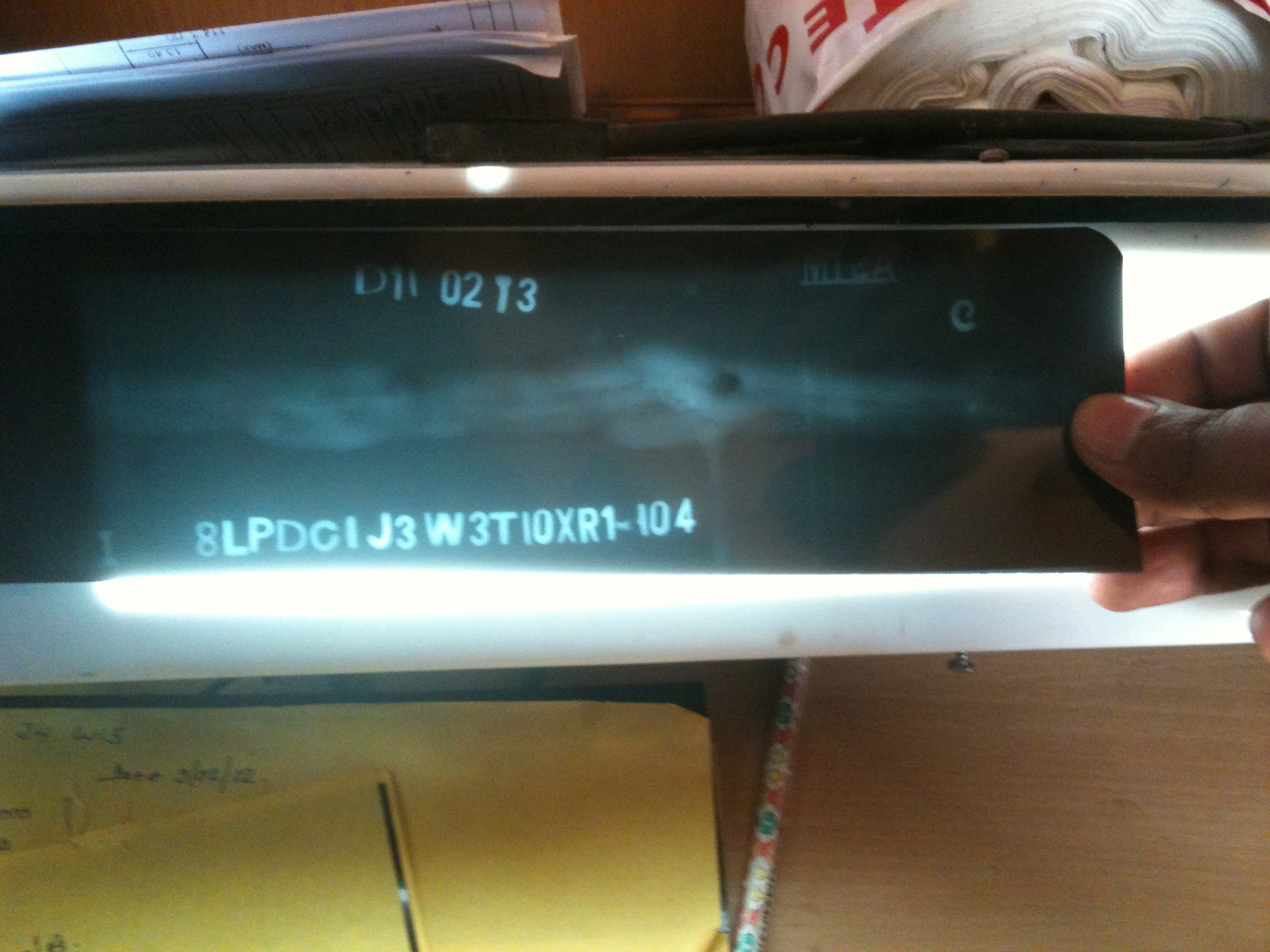

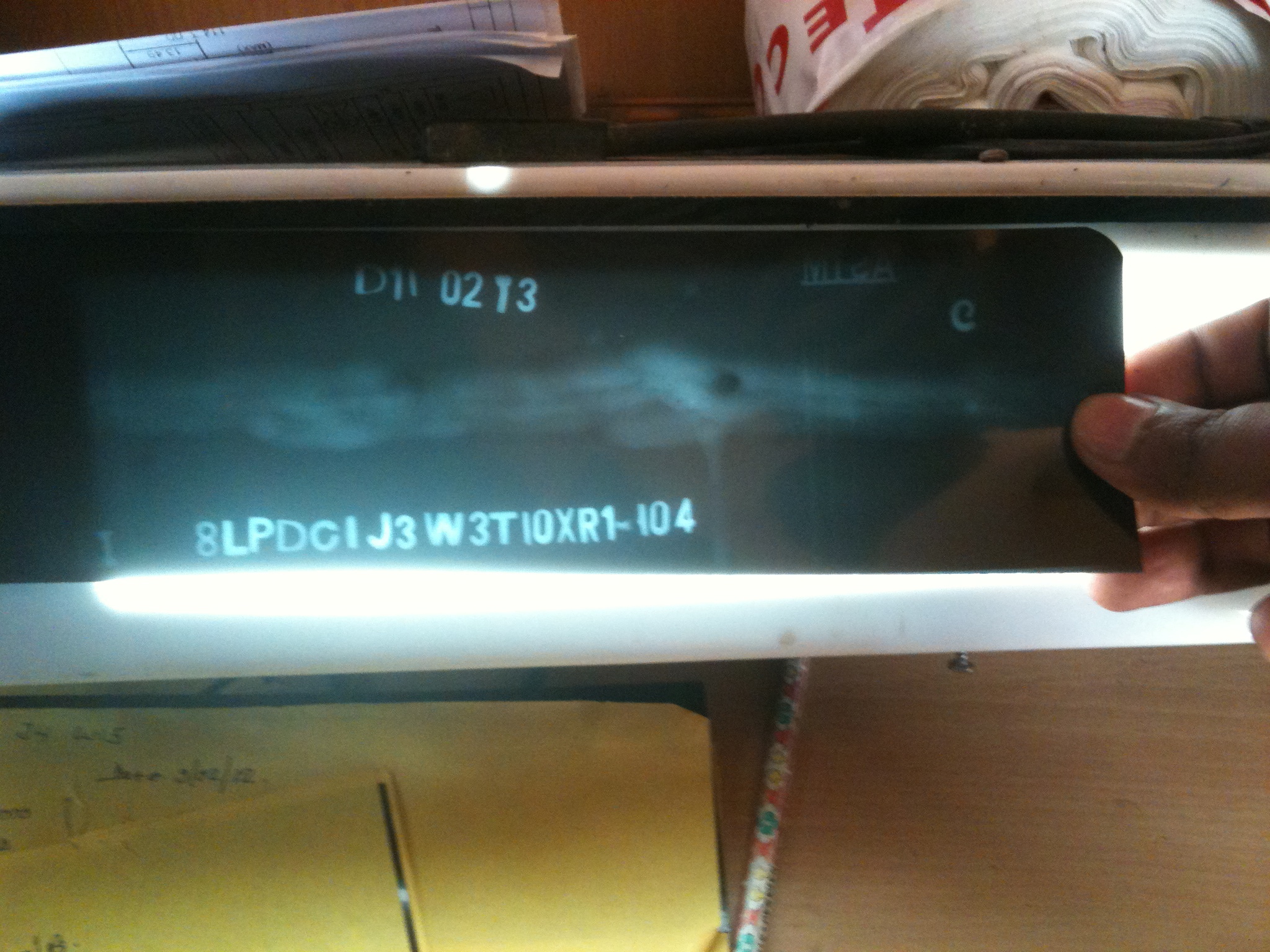

Radiography testing (RT) is a non destructive testing (NDT) technique used to evaluate the internal structure and integrity of materials, primarily metals. It involves the use of X rays or gamma rays to create an image of the materials internal structure, which can then be analyzed for defects or irregularities. Radiography testing is commonly used in industries such as manufacturing, construction, and aerospace to ensure the safety and quality of metal components.

The process of radiography testing typically involves the use of a radiography machine, which emits a beam of radiation that penetrates the material being tested. The radiation is absorbed differently by different materials, and this creates a contrast between different parts of the material on the radiographic film or digital detector. This contrast allows the radiographer to identify any defects or inconsistencies within the material.

Radiography testing can detect a wide range of defects, including cracks, voids, inclusions, and porosity. These defects can be caused by a variety of factors, such as manufacturing flaws, material degradation, or physical damage. By identifying these defects, engineers can determine the safety and reliability of a metal component and take appropriate measures to repair or replace it if necessary.

Overall, radiography testing is a highly effective NDT technique that provides engineers with valuable information about the internal structure and quality of metals. It can help to ensure the safety and reliability of metal components in a variety of industries and is an essential tool in the development and production of high quality metal products.

Other Products in 'Training and Certifications' category

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |