ASNT Level II Visual Testing

Product Details:

ASNT Level II Visual Testing Price And Quantity

- 8000 INR/Number

- 1 Number

ASNT Level II Visual Testing Trade Information

- At our Industrial Facility / Training Institute in Greater Noida

- Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 50 Number Per Week

- 3 Days

- Yes

- Contact us for information regarding our sample policy

- NDT Level II certificate

- North India

- NDT level II in Visual Testing as per ASNT's written practice SNT-TC-1A

Product Description

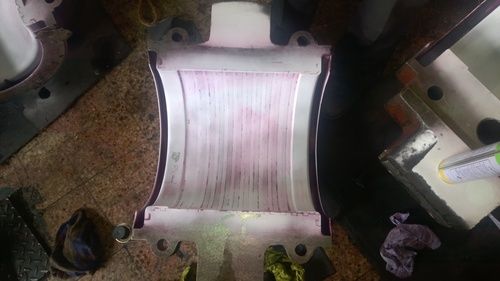

Visual testing is a non destructive testing method that engineers use to assess the condition of mechanical components. This method involves using the human eye to detect any visible surface defects or irregularities that may be present on a mechanical component.

The process of visual testing begins by carefully examining the component under good lighting conditions. Engineers will look for any signs of cracks, corrosion, or other damage that may be visible on the surface of the component. They may also use specialized equipment, such as magnifying lenses or cameras, to get a closer look at the component and capture images for further analysis.

Visual testing is a quick and cost effective testing method, making it a popular choice for many engineers. It is also a versatile method, as it can be used to assess a wide range of mechanical components, from small bolts and nuts to large structures and machines. Additionally, visual testing does not require any special training or equipment, meaning that it can be performed by engineers with minimal training.

However, visual testing does have some limitations. For example, it may not be able to detect defects that are not visible on the surface of the component or that are located in hard to reach areas. In these cases, other non destructive testing methods, such as ultrasonic testing or X ray testing, may be necessary.

In conclusion, visual testing is a valuable non destructive testing method for engineers to assess the condition of mechanical components. It is a cost effective and versatile method that can quickly identify visible surface defects and irregularities. While it has some limitations, it is still a valuable tool in the engineer's toolkit for ensuring the safety and reliability of mechanical components.

Other Products in 'Training and Certifications' category

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese