Eddy Current Testing of Heat Exchanger Tubes (ECT)

Product Details:

Product Description

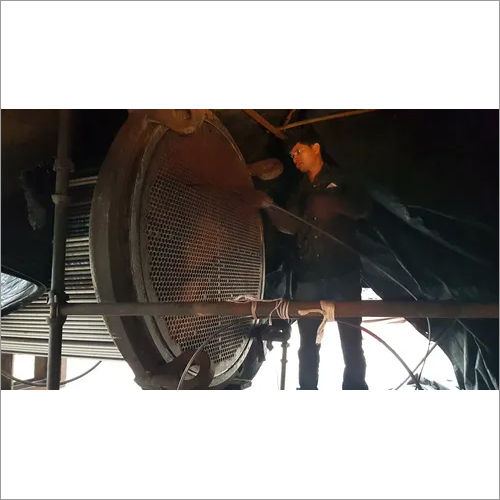

ITE has been performing Eddy Current Testing of tubes for more than a decade.

EDDY CURRENT INSPECTION is based on the principles of electromagnetic induction and is used to identify or differentiate among a wide variety of physical, structural, and metallurgical conditions in electrically conductive ferromagnetic and non ferro magneticmetals and metal parts.

Because eddy currents are created using an electromagnetic induction technique, the inspection method does not require direc telectrical contact with the part being inspected. The eddy current method is adaptable to high-speed inspection and because it is nondestructive, can be used to inspect an entire production output if desired. The method is based onindirect measurement,and the correlation between the instrument readings and the structural characteristics and serviceability of the parts being inspected must be carefully and repeatedly established

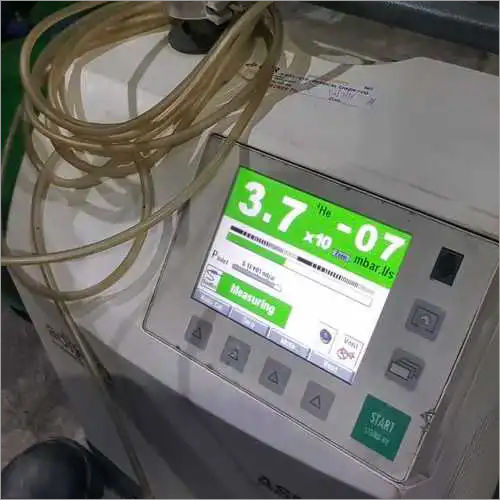

AtITE, we use Olympus MS 5800 for Eddy Current Testing of Tubes in various components like Heat Exchangers, Reactors, Condensers, etc. All those tubes which are non ferromagnetic in nature like made from the alloys of Aluminium,Copper, Austenitic Stainless Steel, Titanium, etc. are tested. We have a formidable customer base for ECT like IOCL, NFL, KSFL, NPL, IFFCO, etc. to namea few.

Locations servced are Delhi, Uttar Pradesh, Maharashtra, Punjab, Rajasthan, Bihar, Gujarat, Haryana, Uttarakhand, Jammu & Kashmir, Himachal Pradesh, Madhya Pradesh, Sikkim, Arunachal Pradesh, Nepal and rest of India.

Other Products in 'Advanced Non Destructive Testing' category

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese