Positive Material Identification

Product Details:

Product Description

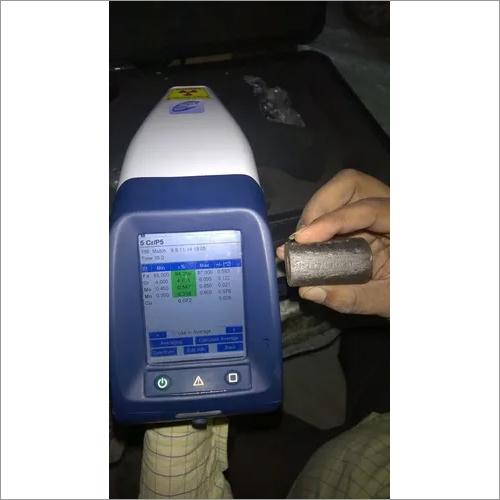

Positive MaterialIdentification (PMI) is one of the more specialised non destructive testingmethods. With positive material identification the alloy composition ofmaterials can be determined. If a material certificate is missing or it is notclear what the composition of a material is, then PMI offers the solution.Because specifications for materials used in industry are increasingly morespecific, the need for PMI testing has been on an increase for the past severalyears. Periodic plant maintenance shutdowns are less frequent and consequentlythe materials used in the plant are in use longer. A wider variety of alloysthat are indistinguishable to the eye are being used in process plants. Whenfacility and inspection staff replace components, they must be able toguarantee that the new part matches required specifications. Recent industrialaccidents have cost the lives of workers and heightened the awareness of theneed for accurate and comprehensive PMI inspections.

The XRF principle (x rayfluorescence) is one of the methods for PMI. Equipment used contains lowradioactive sources (isotopes) or x-ray tubes. The exposed material reflectsthe radiation, generating energy. As every element has it's own atomicstructure, this reflection will generate a different energy level for everyelement. This energy is measured and detected, thus identifying the alloyelements. The other method for PMI is Spark emission spectrography.Spectography is based on optical emission. The equipment consists of a probewhich releases a spark that is used to vapourise the material being analysed.The atoms and ions in this vapour produce a spectrum which can be opticallymeasured and then recalculated to determine the components of the material.Material properties like structure difference and heat treatments have noinfluence on the results of the PMI measurements. However, it is important thatthe surface is identical to rest of the material. Oxides, coatings and dirt onthe material will influence the identification results. Also the surface mustbe smooth. Elements that can be identified using PMI include: Ti, V, Cr, Mn,Co, Fe, Cu, Zn, Ni, Se, Nb, Mo. Interesting to know is that the exposure ofradiation is sufficiently low, so that extra safety measures are not required.When dealing with exploitation licenses and preventive maintenance of technicalinstallations, Non Destructive Testing and Examination (NDT / NDE) areindispensable techniques. NDT / NDE offer also the necessary guarantees whenquality, expense saving, business security and safety is in order, for bothexisting and new installations. NDT / NDE decrease the risk of leakage or otherdefects, which increase the business integrity and safety within theinstallation and can save expenses.

Product details

| Material Type | SS,Copper,Nickle,Steel |

| No Of Unit To Be Tested | 200 |

| Industry Type | Refineries, Production, Chemical Plant |

| Location/City | Pan India |

| Sample Test Location | Customer Place |

| Product Type | Alloy |

| Mode Of Report | Soft Copy |

| Usage/Application | Material Sorting |

| Test Location | Customer Place |

| Application Type | Material Sorting |

| Testing Type | Non Destructive Testing Services |

| Service Duration | As desired by Customer |

| Destination | All India |

| Type Of Service Provider | Inspection and Testing Engineers |

| Need Test Result | <2 Hours |

| Calibration Check Required | Yes |

| Need Standard Certification | Yes |

Other Products in 'Non Destructive Testing' category

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese